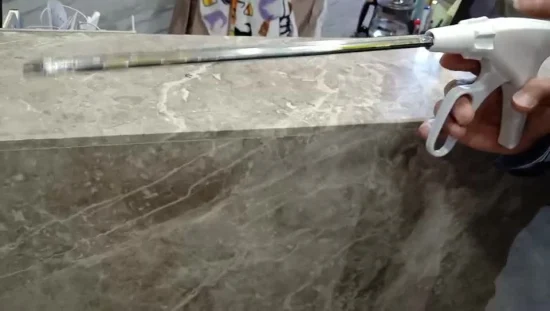

Standard Size Silicone Cap and Plug Masking Solution

Product show 1. rubber molded products: 2. Auto rubber parts: Other main products: ADVANTAGED SERVICE TO YOU: 1.Lower fr

Basic Info

| Model NO. | according to your requirements |

| Material | Silicone Rubber |

| Application | Machinery, Industrial Component, Electronic Product, Vehicle, Household Appliance |

| Effect | Fixture&Sealing |

| Cross-Section Shape | Rectangle Ring |

| Hardness | 30-90 Shore a |

| Tensile Strength | >=17MPa |

| Elongation at Break | >=300% |

| Creep | 15% |

| Working Temperature | -40~230 Celsius Degree |

| File | Format Auto CAD, Pdf, JPG |

| Function | Masking Solution |

| Transport Package | as Your Request |

| Specification | customed |

| Trademark | BRP |

| Origin | China |

| HS Code | 4016931000 |

| Production Capacity | 1000000PCS/Year |

Product Description

| Product Description | ||

| Products | Name | Standard Size Silicone Cap and Plug Masking Solution |

| Products category | rubber molded product | |

| Material | EPDM,NR,SBR,Nitrile, Silicone, Fluorosilicone, FKM, Neoprene, Urethane(PU), Polyacrylate(ACM), Ethylene Acrylic(AEM), HNBR, Butyl(IIR), plastic like material (TPE, PU, NBR, silicone, NBR+TPE etc) | |

| Size | All size and thickness available. | |

| Shape | capable of all shapes as per drawing | |

| Color | Natural,black, Pantone code or RAL code, or as per client's samples or requirements | |

| Hardness | 20°~90° Shore A, usually 30°~80° Shore A. | |

| Surface finishing | Texture (VDI/MT standard, or made to client's sample), polished (high polish, mirror polish), smooth, painting, powder coating, printing, electroplating etc. | |

| Drawing | 2D or 3D draiwng in any image/picture format is OK | |

| Free sample | Yes | |

| OEM/OEM | Yes | |

| Application | Household, electronics, for vehicles like GM, Ford, Renault, Honda. Machinery, hospital, petrochemical, Military and Aerospace etc. | |

| Market | Europe, North America, Oceania | |

| Quality certification | ISO 90001:2008, TS16949, FDA, REACH, ROHS, SGS | |

| QC | Every order production will get more than 10 times regular check and 5 fives times random check by our professional QC. Or by Third party appointed by customer | |

| Mold | Molding Process | Injection molding, mold processing, extrusion |

| Mould type | processing mold, injection mold, extrusionmold | |

| Machines | 350T vacuum pressing machine and other pressing machine at 300T,250T and so on | |

| Tooling equipment | Rubber tension tester, Rubber vulcanization instrument, Durometer, calipers, ageing oven | |

| Cavity | 1~400 cavities | |

| Mould Life | 300,000~1,00,000 times | |

| Production | Production capacity | finish each mold of product in 3 minutes and working on 3 shifts within 24 hours |

| Mold lead time | 15~35 days | |

| Sample lead time | 3~5 days | |

| Production time | usually 15~30 days, should be confirmed before order | |

| Loading port | Hangzhou, Shanghai, Ningbo or as required | |

Product show

1. rubber molded products:

2. Auto rubber parts:

| PRODUCTS STANDARD | |

| QUALITY CERTIFICATE | ISO 9000, TS16949, FDA, REACH, ROHS |

| MATERIAL STANDARD | ASTM D2000, SAE J200, JIN OR AS PER DRAWING |

| TOLERANCE STANDARD | RMA A1,A2,A3, DIN ISO 3302-1,DIN-7715/BS-3734 OR AS PER DRAWING |

| COLOR STANDARD | PANTONE COLOR, RAL COLOR |

| QUALITY REPORTS | PPAP, RAW MATERIAL REPORT, TEST REPORT, OFFCIAL REPORT BY THIRD PARTY |

Other main products:

ADVANTAGED SERVICE TO YOU:

1.Lower freight of sample or goods by DHL, as we have DHL account with bigger discount.

2. Lower price from less management cost, less labor cost and land cost from our new plant.

3. Less FOB cost as it is only 1~3 hours drive from our factory to Ningbo or Shanghai port and airport.

4. More solution for plastic/rubber material and prodution as our boss and engineers have 30 years of experiences in rubber plastic industry.

5. More Effective service: prompt reply for your e-mail within 6 hours, good solution for any problems within 12 hours.

6. More advantaged products: rubber molded/injection parts, plastic injection parts, and silicone extrusion parts.

| Order Solution | |

| Order | OEM or ODM welcome. Free sample or slab/button of material for your quality evaluation, mold sample in accordance with drawing for approval of mass production, |

| Payment terms | L/C, T/T, WEST UNION, MONEYGRAM, PAYPAL, ESCROW |

| Lead time | 3~5 weeks for mold production, and 1~2 weeks for mass production |

| Package | As per customer's favour. Shock-absorbing bags, Cartons, Wooden box, and wooden or plastic pallet, |

| Delivery term | FOB CHINA, CIF destination port, DDP customer's warehouse/address of goods |

| Shipment | By air mail, by sea, by express like DHL, Fedex, UPS, TNT, EMS |

| Quality Control | Sample approval before order, QC test report(maybe by third party) before balance. |

Send to us